Semiconductor solutions

In the semiconductor manufacturing process, wafers are following a trend toward ever thinner thicknesses. Nikon s outstanding proprietary technology makes optimal solutions for these “no-error” market.

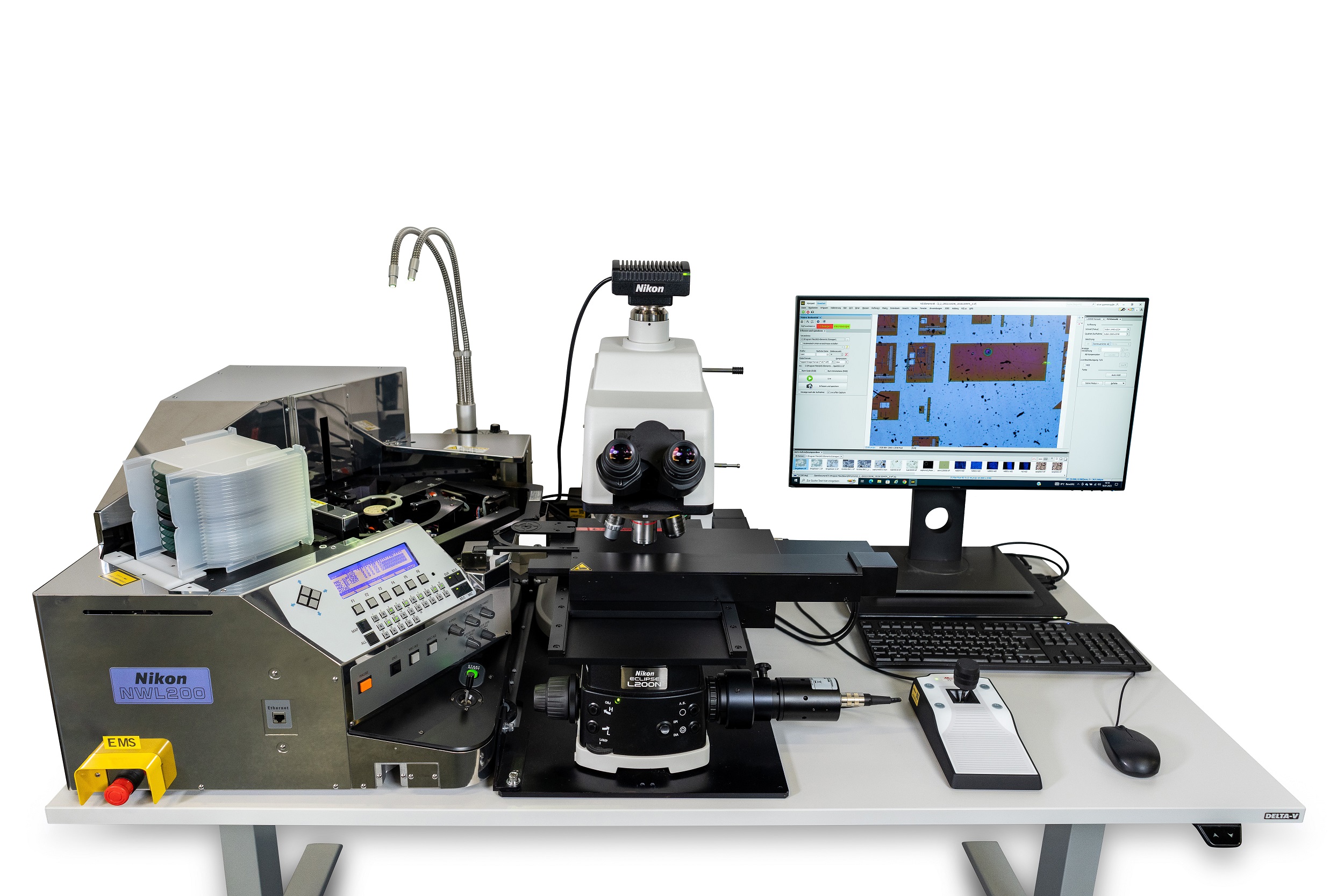

NWL200: Nikon Wafer Loader 200

- Fully secured wafer loader to our L200N microscopes for full manual or automated inspection.

- Incl: wafer alignment, cross-slot-detection, mark detection (notch, flat or double flat), cassette programs, sample programs, good/not-good put back, 6 & 8 inch…

- Option: Macro inspection, Macro image capturing, IR, …